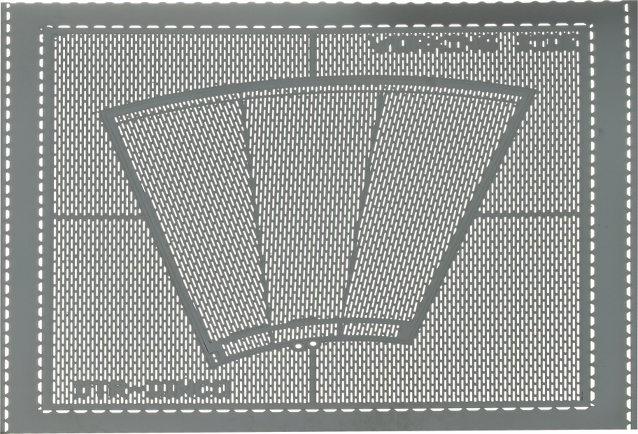

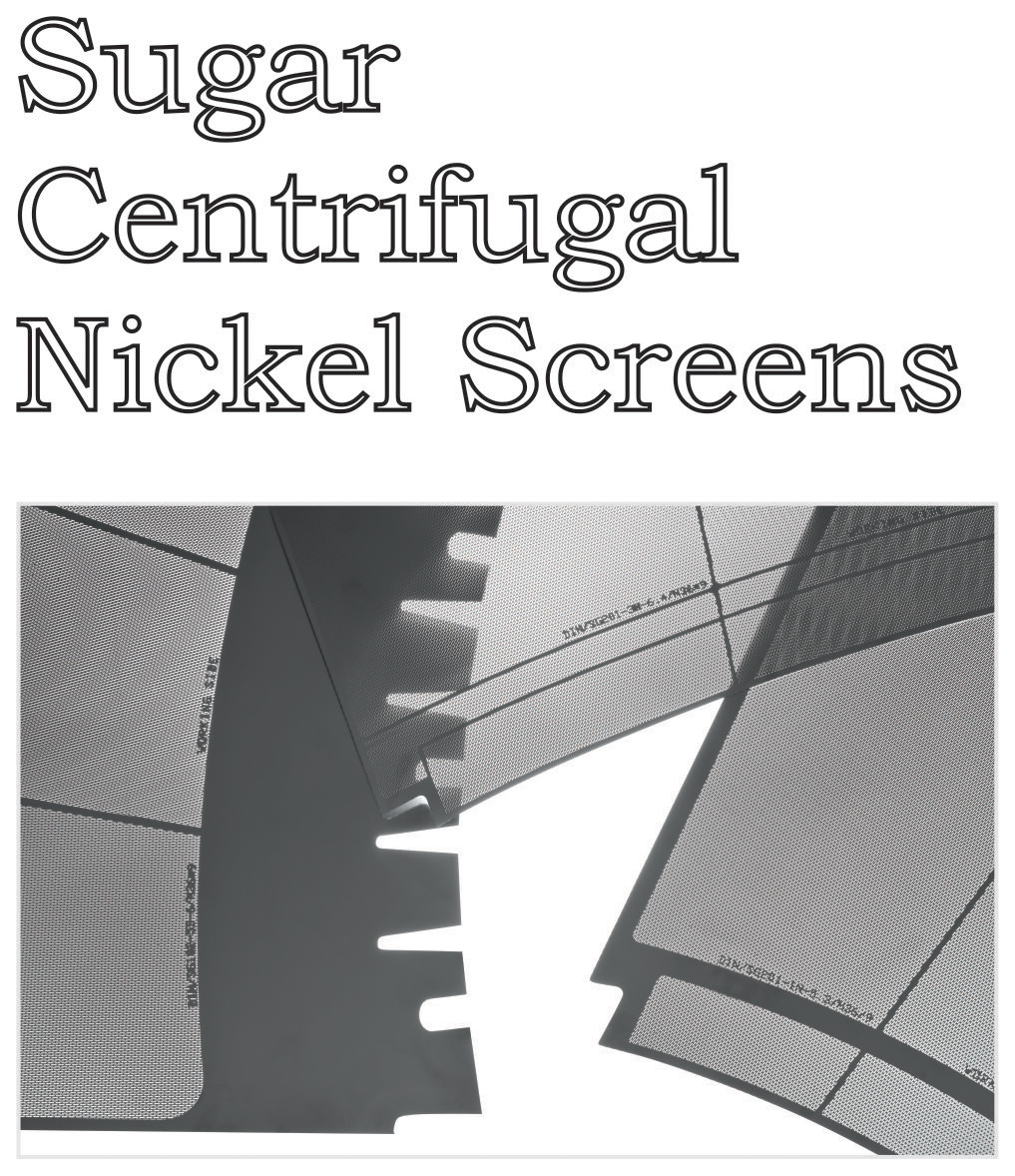

DTR manufactures Premium Chrome-Plated Electroformed Nickel Screens equipped with the latest Technology in our State-of-the-Art Facility in Haryana, India. We specialize in manufacturing High-Quality, High-precision Micron Filter parts, such as Nickel Screens. These advanced Metal Filters boast incredibly very Fine Micron Meshes, so minute that their Aperture is less than the Material's Thickness, representing a manufacturing capability almost rarely possible to replicate with any alternative processes. This is achieved through Litho-based Micro-Technology which when advanced to Nano-Technology is backbone for cutting-edge applications like Semiconductors, Printed/Integrated Circuit boards, Chips etc.

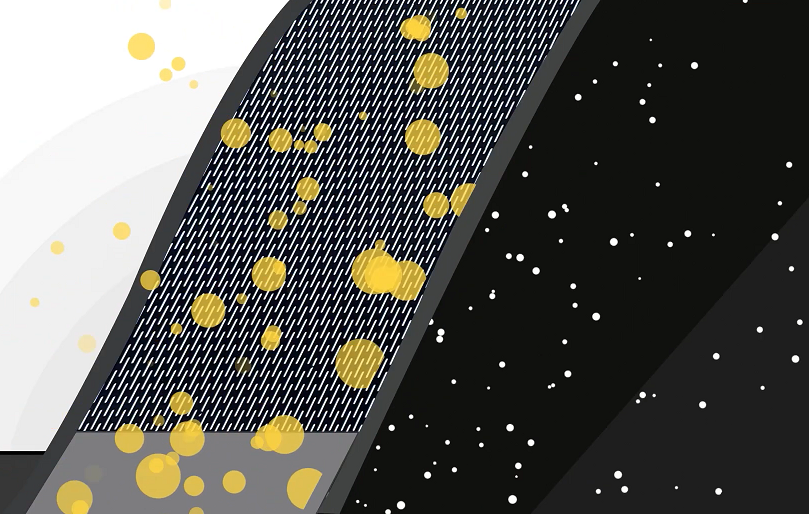

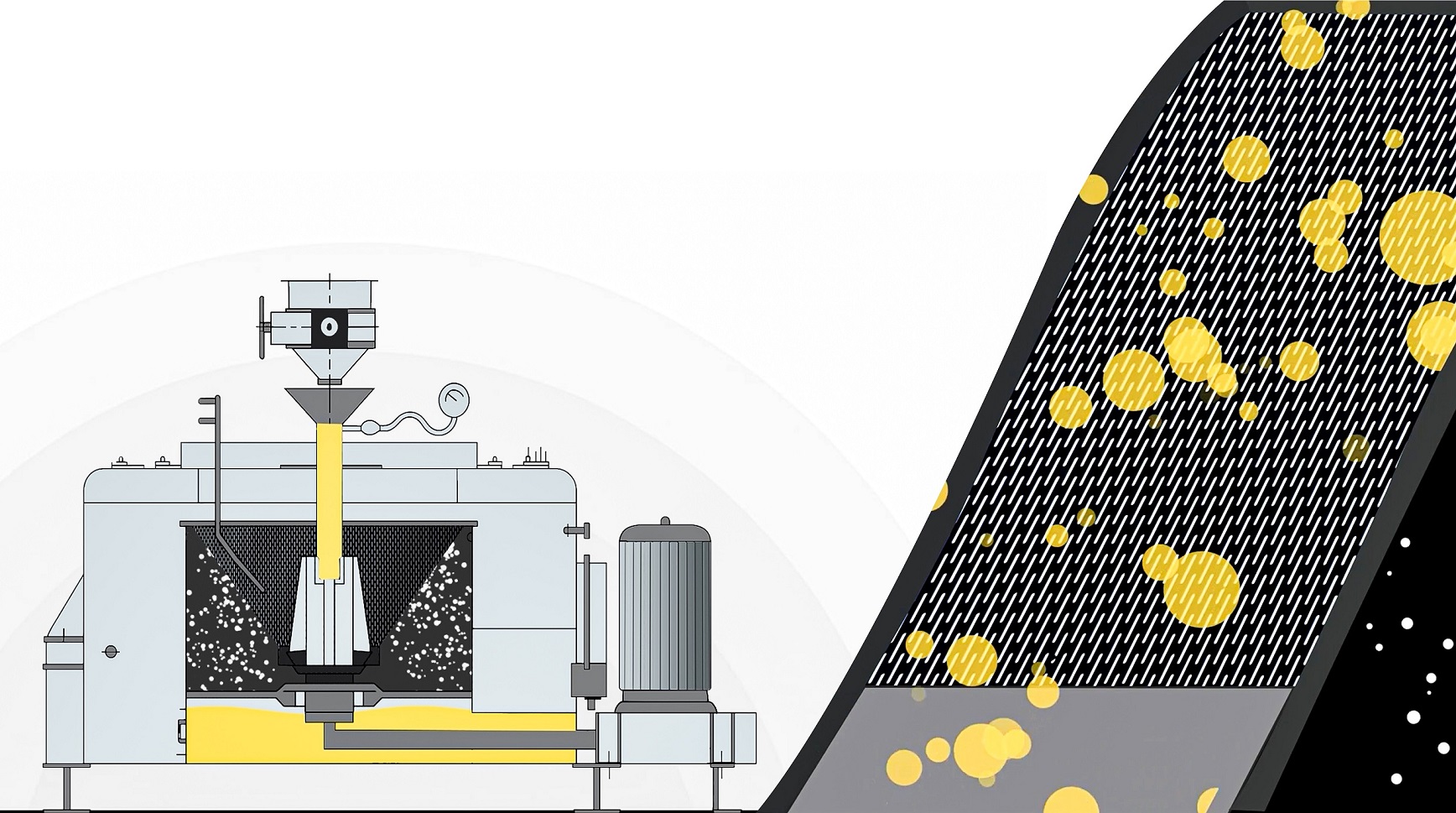

These Nickel Screens are used for uninterrupted separation of fine sugar crystals from the molasses (or syrup), particularly for low-grade massecuites in 'B' and 'C' Continuous Centrifugals. This effectively remove the less viscous and denser liquid molasses film that adheres to the surface of sugar crystals separated through Micro precision Nickel Screens.

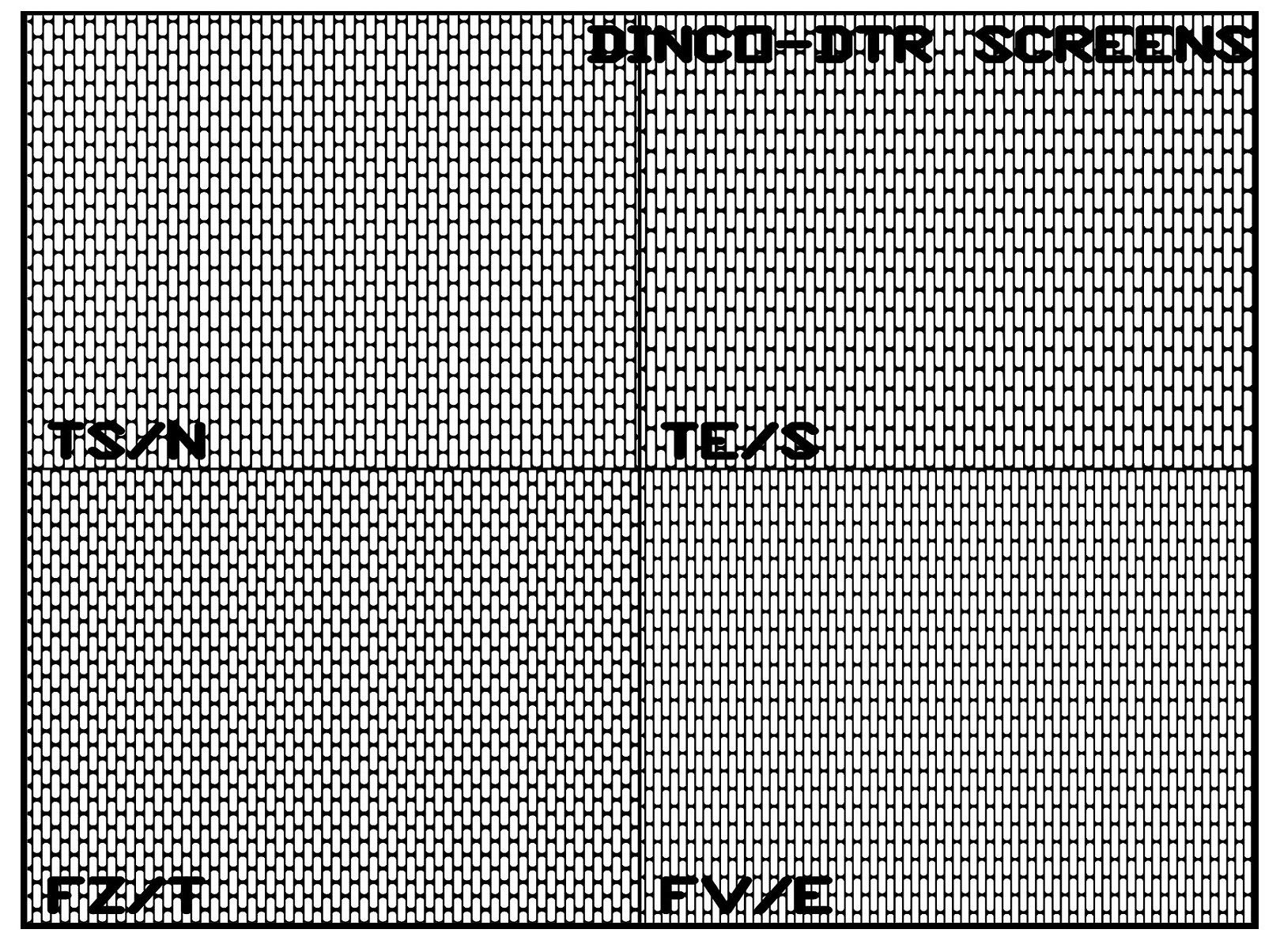

DTR is part of the DINCO group, with a legacy of over 51 years as a leading supplier of Filter Screens for the Food and Sugar industries, expanded its expertise to include specialized Nickel Micro Screens as well.

These Nickel Screens are used for uninterrupted separation of fine sugar crystals from the molasses (or syrup), particularly for low-grade massecuites in 'B' and 'C' Continuous Centrifugals. This effectively remove the less viscous and denser liquid molasses film that adheres to the surface of sugar crystals separated through Micro precision Nickel Screens.

DTR is part of the DINCO group, with a legacy of over 51 years as a leading supplier of Filter Screens for the Food and Sugar industries, expanded its expertise to include specialized Nickel Micro Screens as well.